(image source)

(image source)

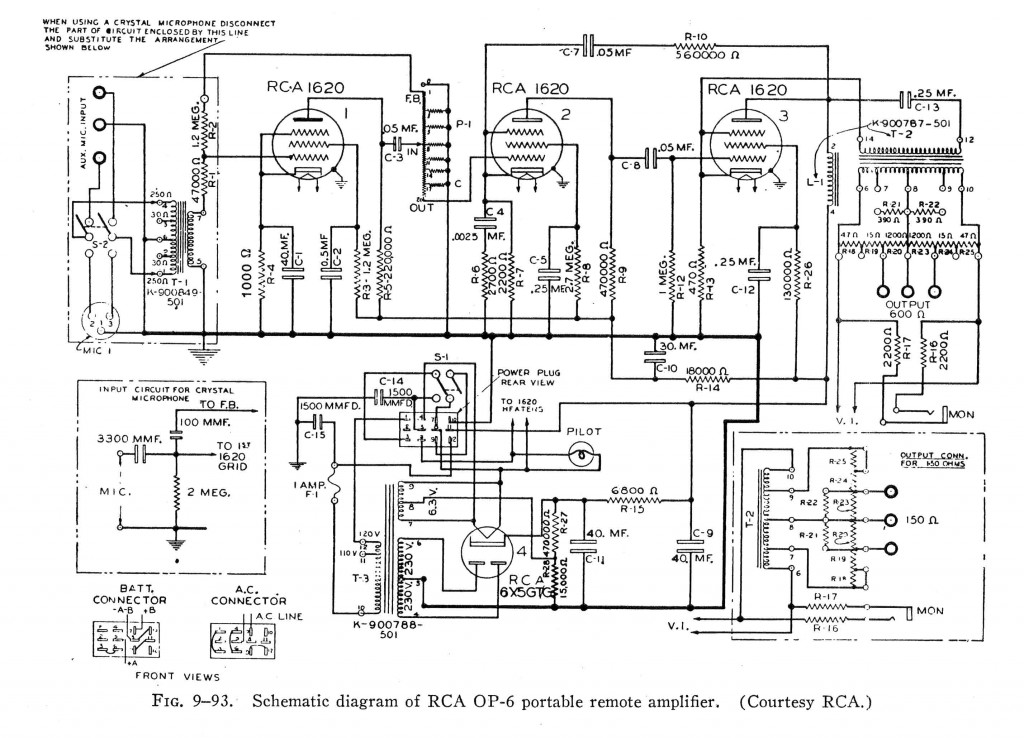

The RCA OP-6 ‘Portable Amplifier’ is one of a handful of truly visually-iconic vintage mic preamps. The OP-6 was designed as a “remote,” as-in, ‘on-location’ single-channel mic preamp for radio station broadcasts. It uses three 1620 (6J7) tubes – most mic pre designs of the period use two. Furthermore, the 1620s are in pentode operation rather than triode. The result: a ton of gain. 95db, apparently. This is almost twice as much gain as the classic RCA BA1 and BA2 mic pres. OP-6s are in high demand – click here for a seller asking $2900. Further indication: Blackbird Rentals in Nashville has thirteen in stock as rental units. The first time I heard an OP-6 in use was at Blackbird; I was producing/directing a live-in-the-studio performance for Martina McBride and John McBride was engineering; he was using the OP-6 for something… I can’t remember what exactly. Anyway, it caught my eye and we talked about it a bit; later I learned that he has an especially strong appreciation for these units. A strong endorsement coming from the man who likely owns more vintage pro audio gear than anyone who ever has or ever will live.

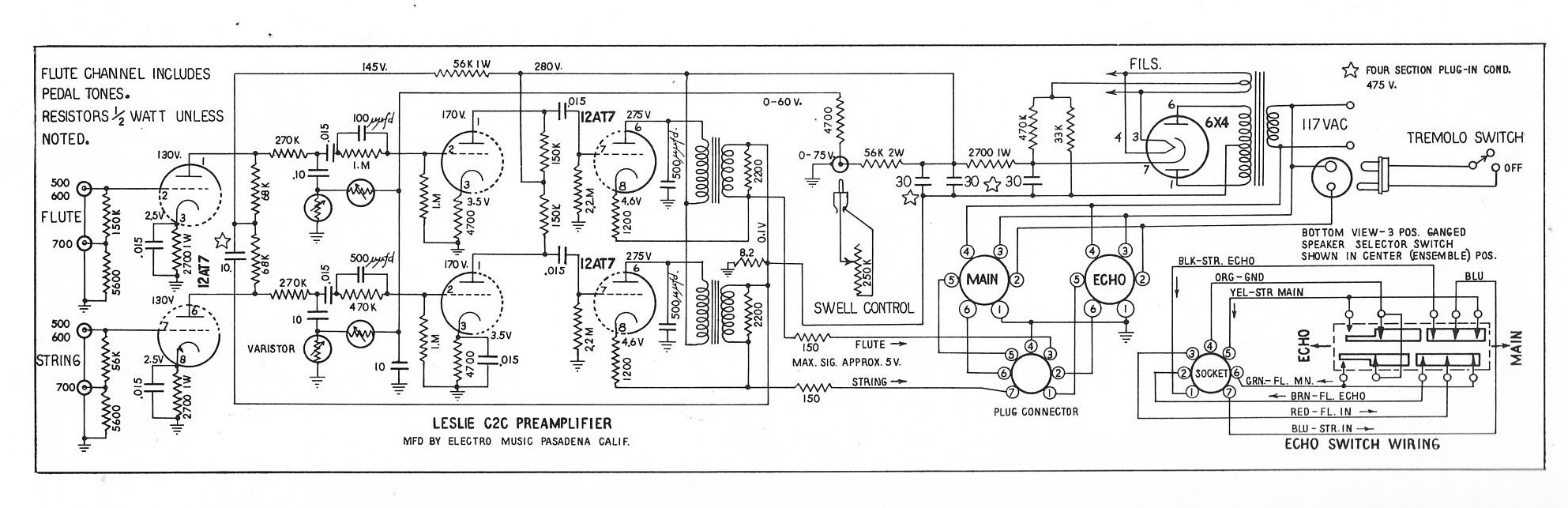

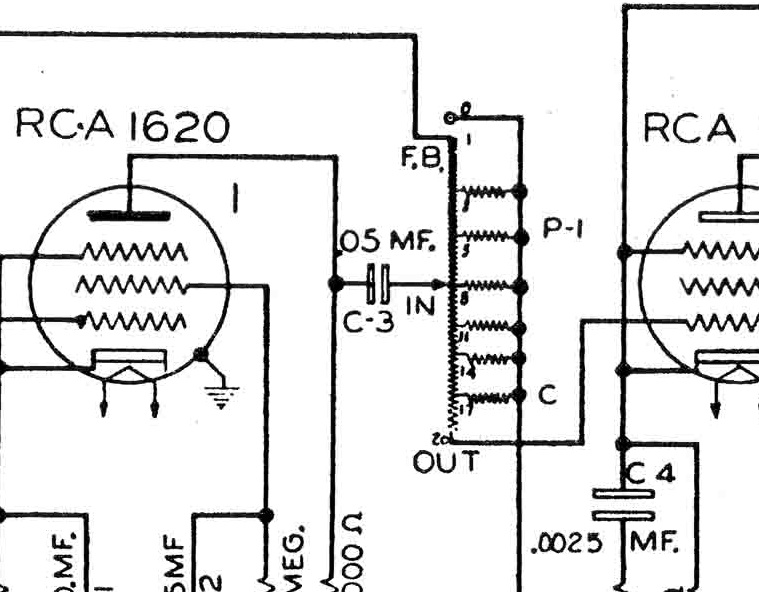

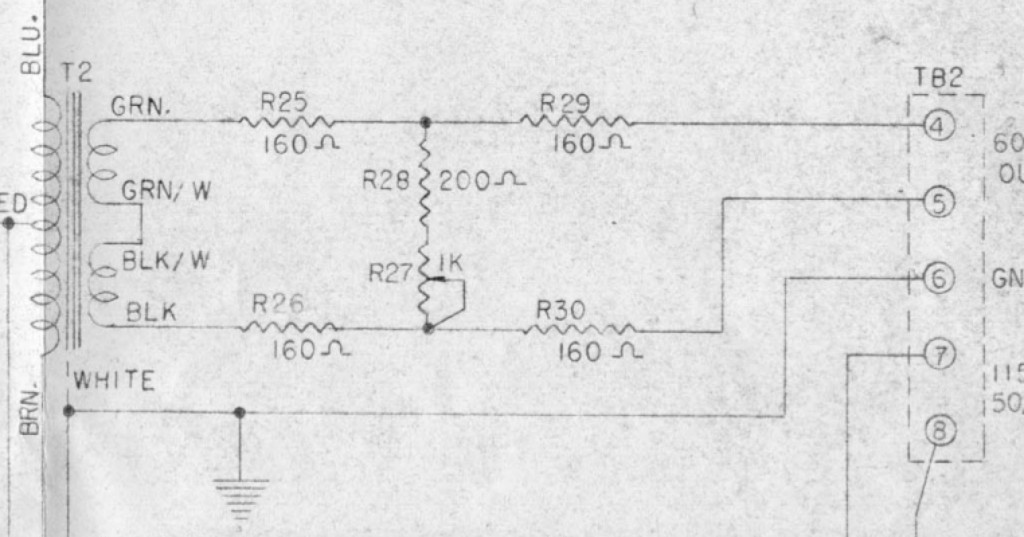

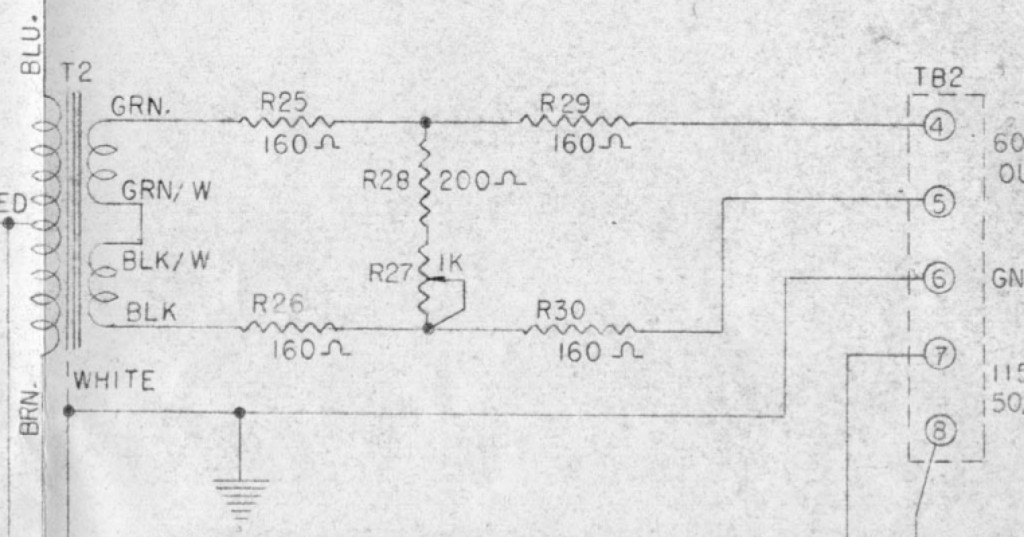

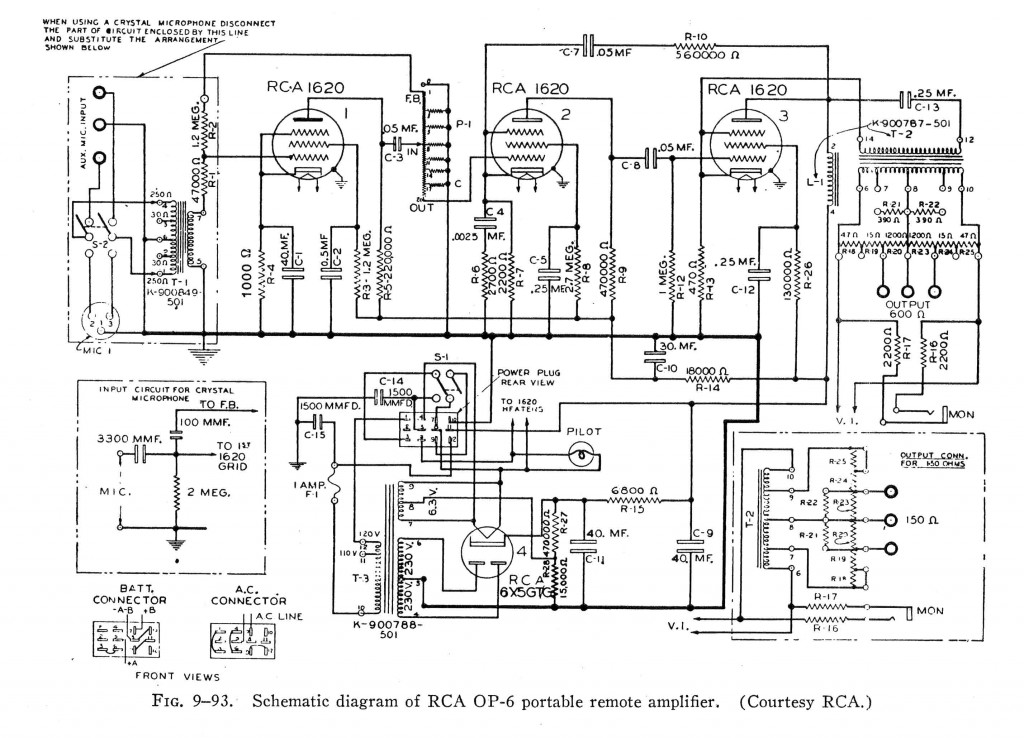

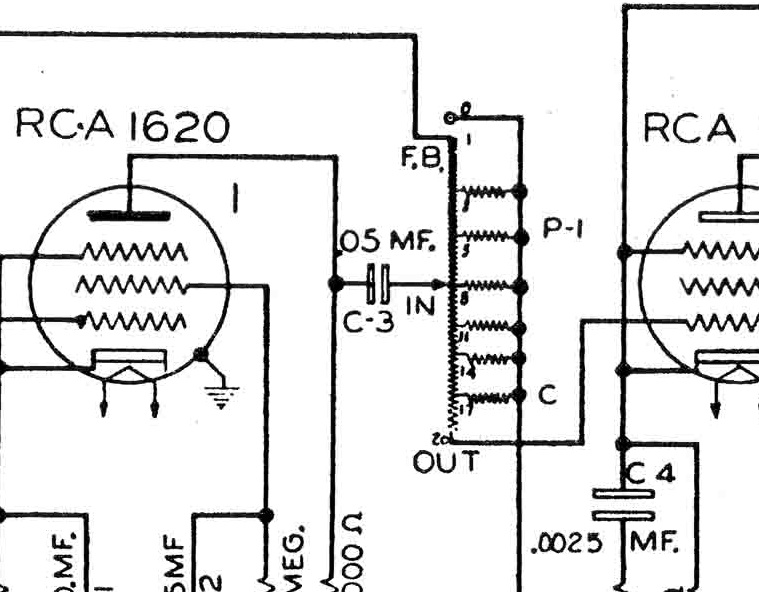

The OP-6 schematic is pictured above (this file is readily available in high-res on the internet). So anyhow, if we consider how in-demand the OP-6 is, it seems striking that no one offers a modern equivalent for sale, even on a small-scale level. If you take a close look at the circuit, the reasons become apparent. There are two big obstacles to re-creating even a semblance of an OP-6. First is the input attenuator:

The OP-6 schematic is pictured above (this file is readily available in high-res on the internet). So anyhow, if we consider how in-demand the OP-6 is, it seems striking that no one offers a modern equivalent for sale, even on a small-scale level. If you take a close look at the circuit, the reasons become apparent. There are two big obstacles to re-creating even a semblance of an OP-6. First is the input attenuator:

Sure, it’s a voltage divider; probably constant impedance; but what exactly are the values? And what about that value of that feedback path issuing from the attenuator back to the input stage? If I could get my hands on an original OP-6 and open up the attenuator, sure I could maybe sort it out. But I imagine that re-creating that part on custom order could cost hundreds of dollars; frankly I have no idea.

Sure, it’s a voltage divider; probably constant impedance; but what exactly are the values? And what about that value of that feedback path issuing from the attenuator back to the input stage? If I could get my hands on an original OP-6 and open up the attenuator, sure I could maybe sort it out. But I imagine that re-creating that part on custom order could cost hundreds of dollars; frankly I have no idea.

The second obstacle to re-creating the OP-6 is the output stage choke.

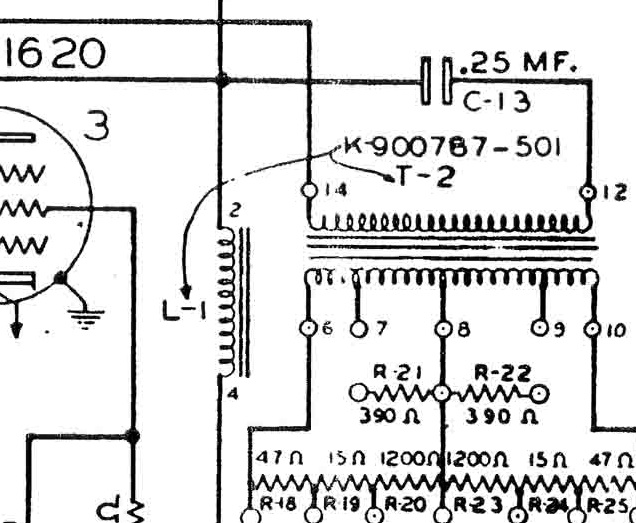

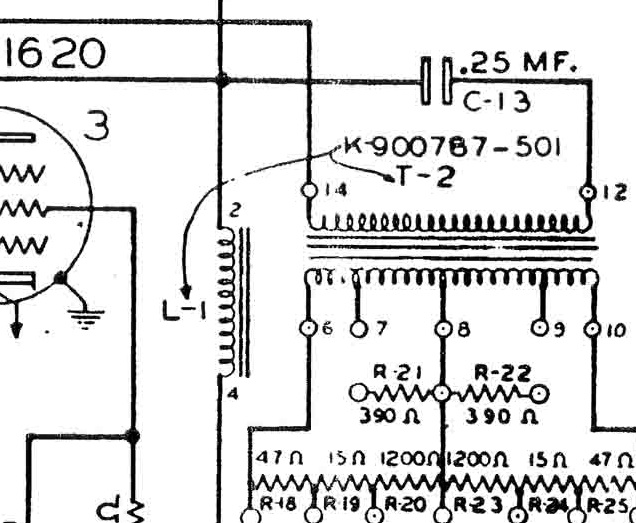

The choke is designated L-1 in the schematic. Curiously enough, it’s actually physically part of the output transformer. Based on this fact, there is zero chance that this was an off-the-shelf choke, say a UTC for example, that we could track down. OK – but the crucial value of a choke in a circuit like this is the inductance. So long as the voltage an current handling values are sufficient, any choke of same inductance should give a similar result. Now again, if I had an original OP-6, I could measure the inductance and maybe a current off-the-shelf part exists to satisfy the requirements. But… I don’t think anyone out there is gonna send me their prized OP-6 to open up. And $2900 is a pretty stiff R+D cost. So what do we do? Well, in the absence of any actual electrical engineering training, I looked for some good advice and then I guessed.

The choke is designated L-1 in the schematic. Curiously enough, it’s actually physically part of the output transformer. Based on this fact, there is zero chance that this was an off-the-shelf choke, say a UTC for example, that we could track down. OK – but the crucial value of a choke in a circuit like this is the inductance. So long as the voltage an current handling values are sufficient, any choke of same inductance should give a similar result. Now again, if I had an original OP-6, I could measure the inductance and maybe a current off-the-shelf part exists to satisfy the requirements. But… I don’t think anyone out there is gonna send me their prized OP-6 to open up. And $2900 is a pretty stiff R+D cost. So what do we do? Well, in the absence of any actual electrical engineering training, I looked for some good advice and then I guessed.

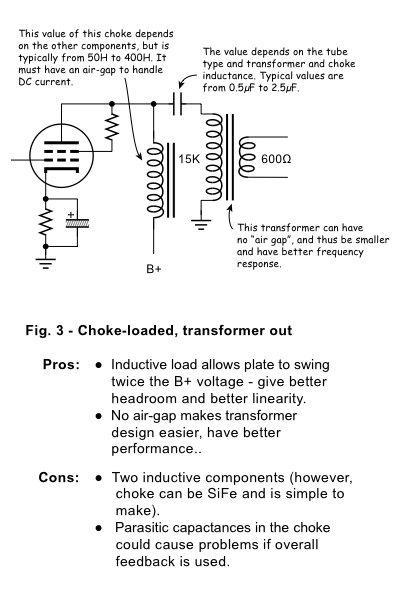

The very friendly+talented John Atwood sent me the diagram above; in response to what I can’t recall. This diagram explains why the choke is necessary in order to get the best possible performance from a single-ended vacuum tube line output stage. Looks pretty similar to our OP-6 output stage, right? Based on this… I made a wild guess. I ordered the very inexpensive Hammond 156C choke. 150mh inductance with 8ma current capacity. 8ma might be a little low, but I have found that Hammond really undersells the specs of their transformers, so I’m not worried.

The very friendly+talented John Atwood sent me the diagram above; in response to what I can’t recall. This diagram explains why the choke is necessary in order to get the best possible performance from a single-ended vacuum tube line output stage. Looks pretty similar to our OP-6 output stage, right? Based on this… I made a wild guess. I ordered the very inexpensive Hammond 156C choke. 150mh inductance with 8ma current capacity. 8ma might be a little low, but I have found that Hammond really undersells the specs of their transformers, so I’m not worried.

Alright so now we’ve got a choke that might work. What about that input attenuator? The best course of action would probably be to get a used 100k Daven T-pad, but without implementing the feedback path that the stock OP-6 attenuator has, it seems like this is slightly pointless vis-a-vis maintaining originality. So instead: I used the input stage from my favorite, yes yet again, the RCA BA-2.

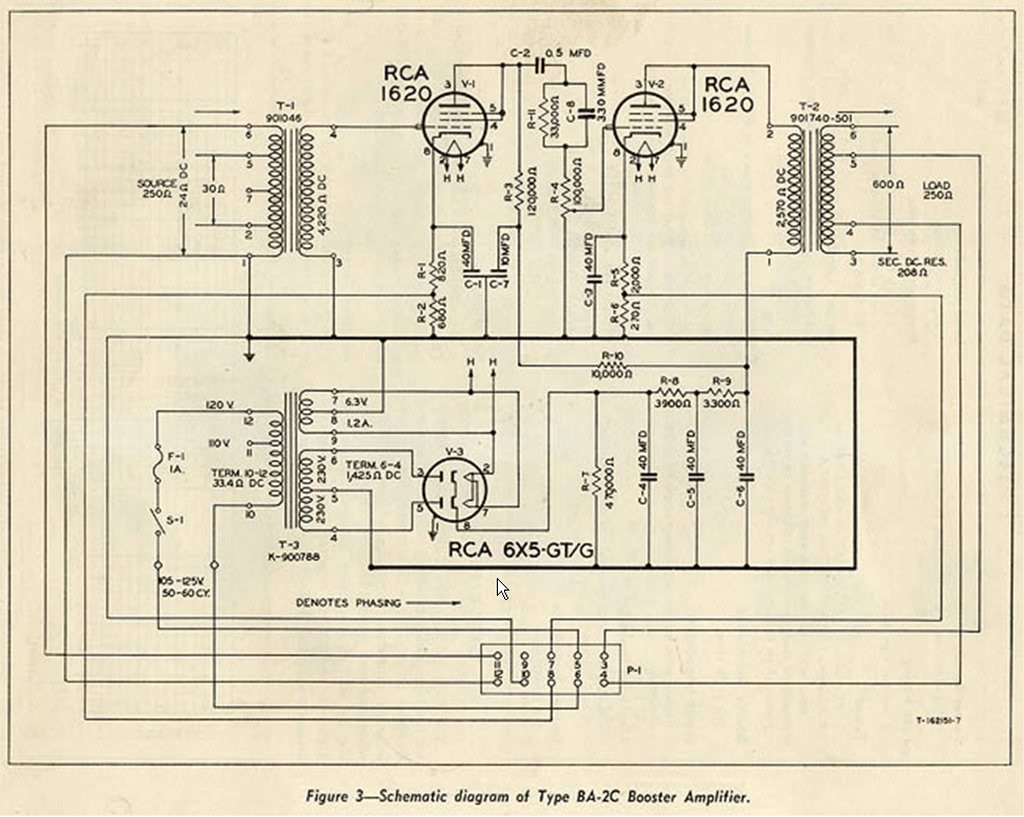

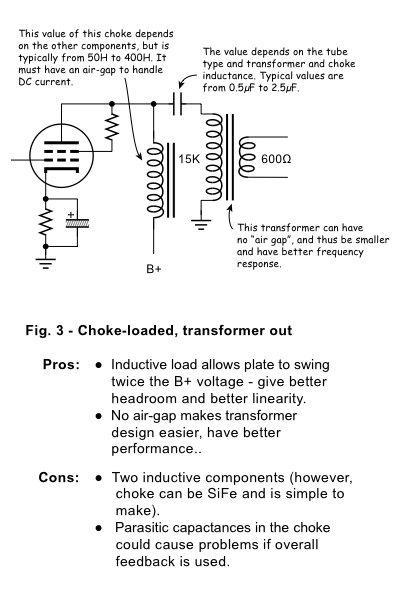

The BA-2 schematic is pictured above. The input stage uses a 1620 tube, wired as a triode, with a 100k ohm pot following it. So I just took this input stage, up to the pot output, and wired it in front of the second two OP-6 stages (starting at the grid of stage #2). When I did this, the whole system worked fine except when the volume pot was a zero (IE., when the grid of tube #2 is shorted to ground). This caused weird noise and a little humming. Not sure if this is due to the negative feedback in that stage, or if this is simply a general characteristic of 1620s when they are run in pentode – but it sounded awful. The easy solution? I added a 1M resistor from the grid to ground, and isolated this from the pot with a 1K grid-stopper resistor. Done and done. The BA2/OP6 Hybrid is born.

The BA-2 schematic is pictured above. The input stage uses a 1620 tube, wired as a triode, with a 100k ohm pot following it. So I just took this input stage, up to the pot output, and wired it in front of the second two OP-6 stages (starting at the grid of stage #2). When I did this, the whole system worked fine except when the volume pot was a zero (IE., when the grid of tube #2 is shorted to ground). This caused weird noise and a little humming. Not sure if this is due to the negative feedback in that stage, or if this is simply a general characteristic of 1620s when they are run in pentode – but it sounded awful. The easy solution? I added a 1M resistor from the grid to ground, and isolated this from the pot with a 1K grid-stopper resistor. Done and done. The BA2/OP6 Hybrid is born.

*************

********

***

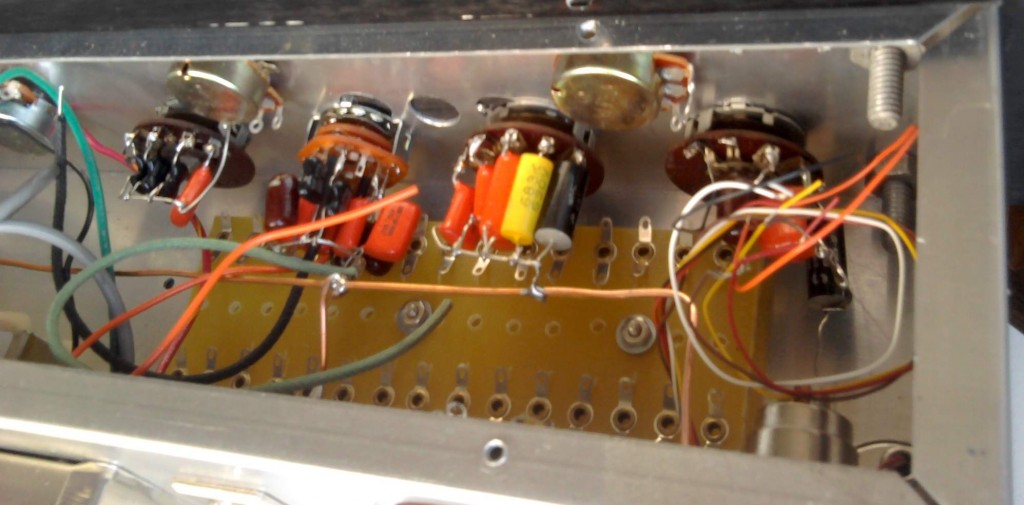

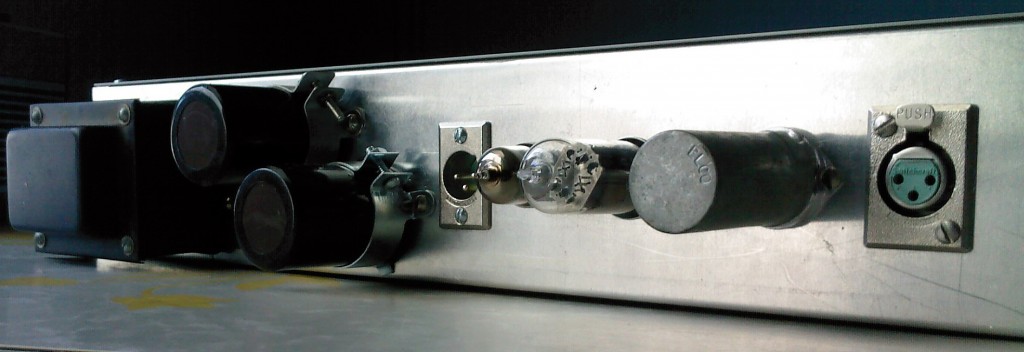

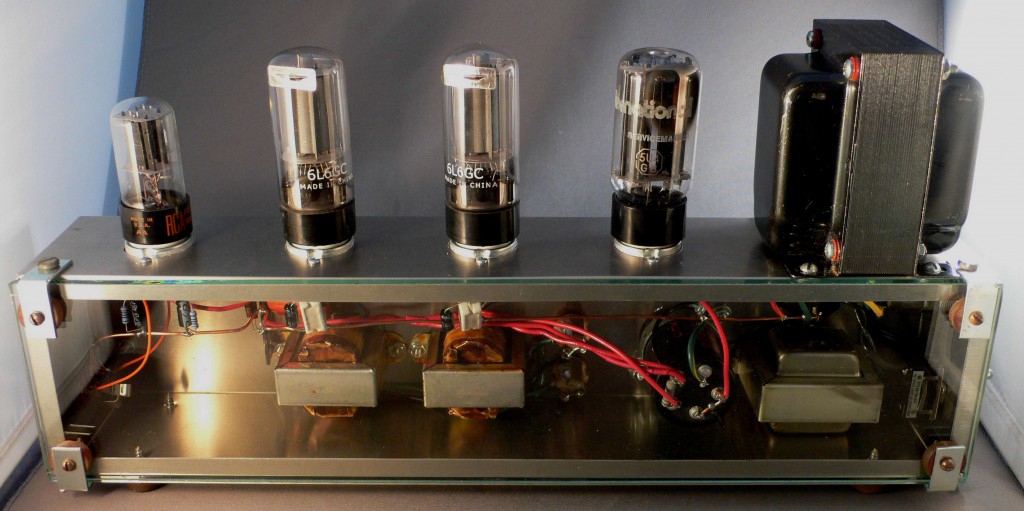

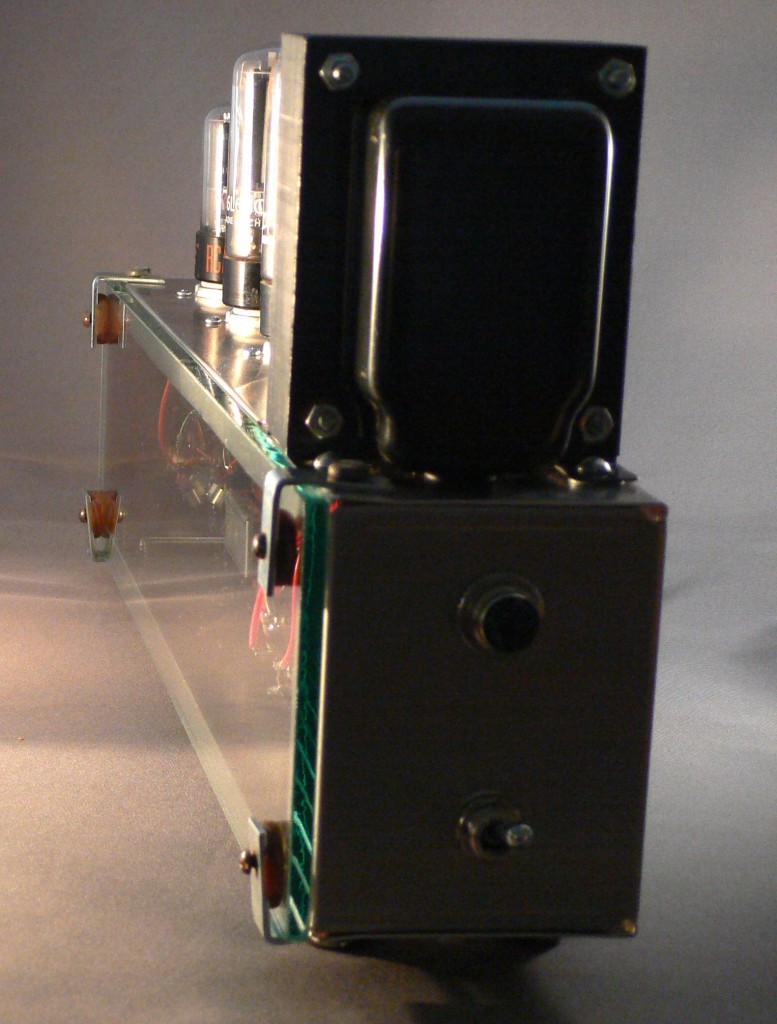

The finished piece is shown above. I used a 6X5 rectifier tube like the OP-6 uses; in fact, with the exception of using DC filament voltage, I kept the power supply the same as the OP-6.

The finished piece is shown above. I used a 6X5 rectifier tube like the OP-6 uses; in fact, with the exception of using DC filament voltage, I kept the power supply the same as the OP-6.

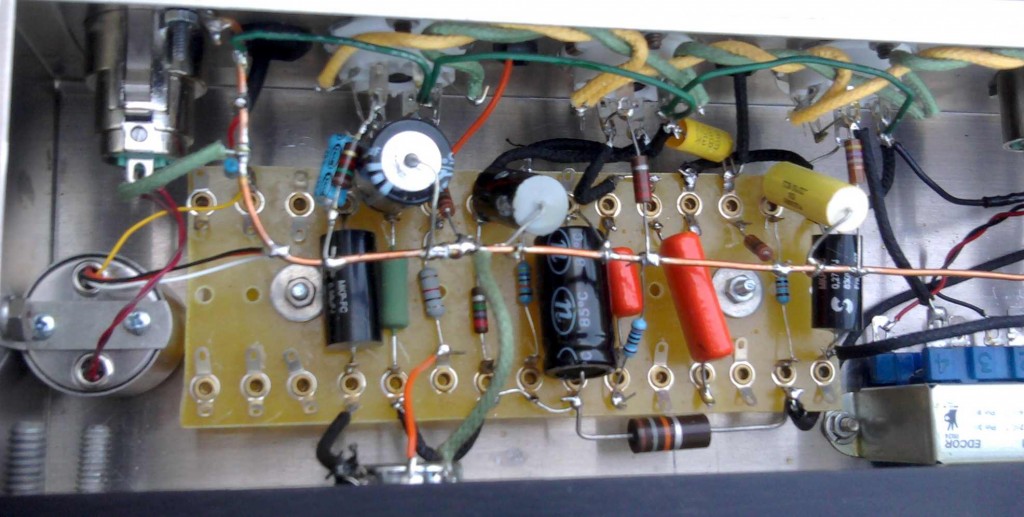

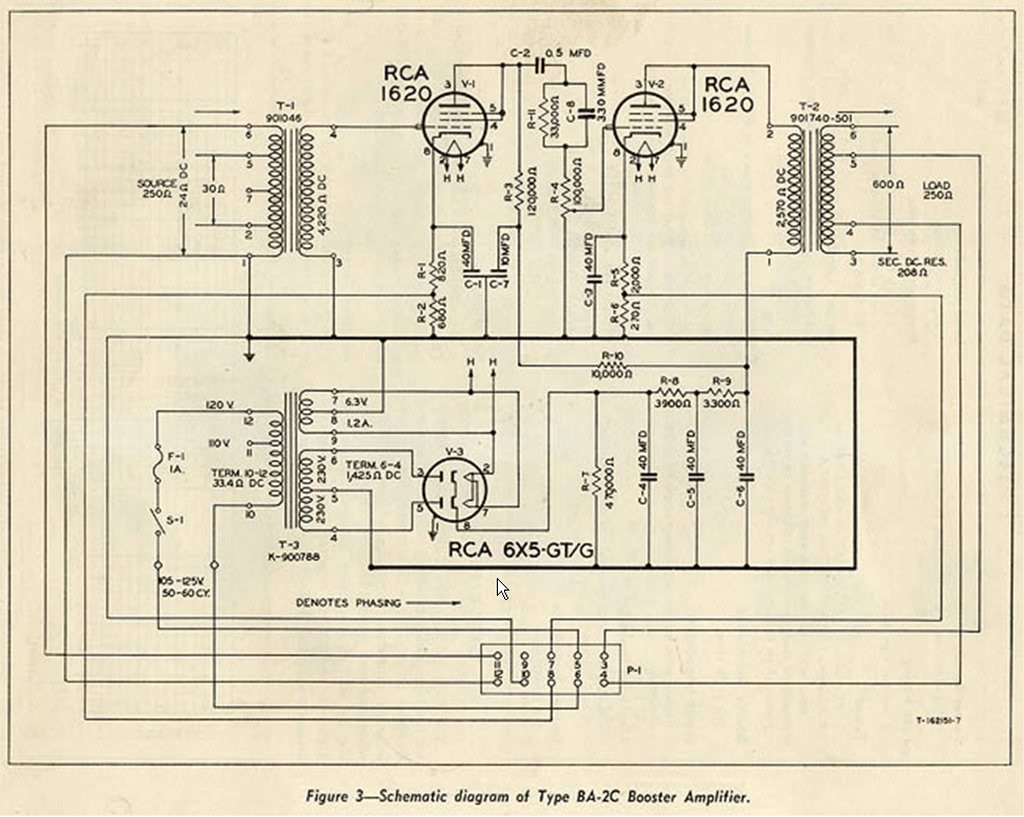

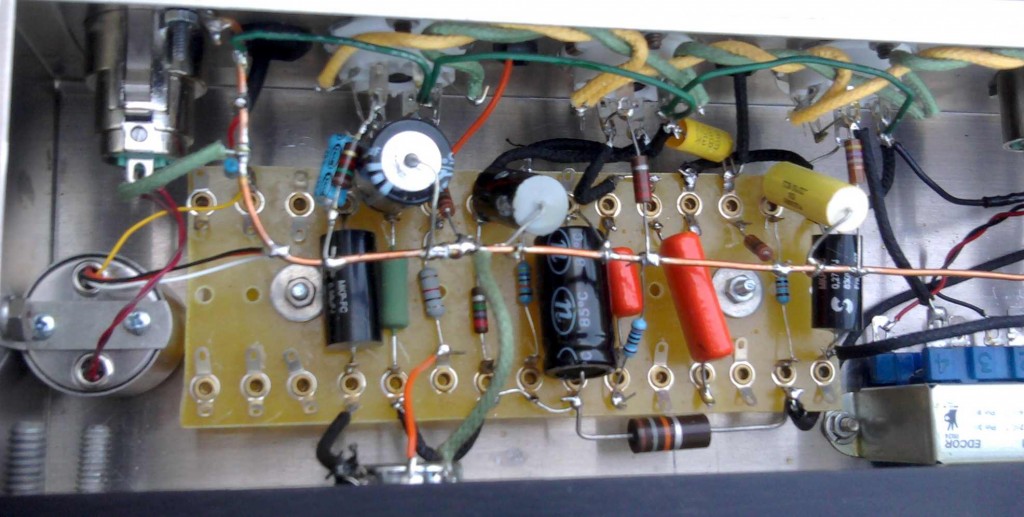

The audio portion of the circuit is shown above. What with the three pentode stages and feedback paths, this is extremely complicated for a mic preamp. A lot of parts. On the left you can see my usual Jensen 115 input transformer. Audio caps are a mix of Solen, sprague, and some random Russian ones. Basically whatever would fit. Resistors are random as well; now that I have confirmed that the piece works well, I will probably replace the carbon-comp resistors in the B+ chain with some quieter modern resistors. On the right is the output transformer. I used an edcor 15K: 600; $10.22!

The audio portion of the circuit is shown above. What with the three pentode stages and feedback paths, this is extremely complicated for a mic preamp. A lot of parts. On the left you can see my usual Jensen 115 input transformer. Audio caps are a mix of Solen, sprague, and some random Russian ones. Basically whatever would fit. Resistors are random as well; now that I have confirmed that the piece works well, I will probably replace the carbon-comp resistors in the B+ chain with some quieter modern resistors. On the right is the output transformer. I used an edcor 15K: 600; $10.22!

Even though this edcor is unshielded, there is zero hum following the volume pot. And as for performance? I did a frequency sweep through the entire unit; response is absolutely flat from 15hz to 10k hz. At 10k there is a rise of about 1db up to 22khz, at which point response begins to fall of pretty rapidly. This is really excellent performance considering the inexpensive transformers. I did not measure the gain but there is a lot of. The output level can get extremely hot.

Even though this edcor is unshielded, there is zero hum following the volume pot. And as for performance? I did a frequency sweep through the entire unit; response is absolutely flat from 15hz to 10k hz. At 10k there is a rise of about 1db up to 22khz, at which point response begins to fall of pretty rapidly. This is really excellent performance considering the inexpensive transformers. I did not measure the gain but there is a lot of. The output level can get extremely hot.

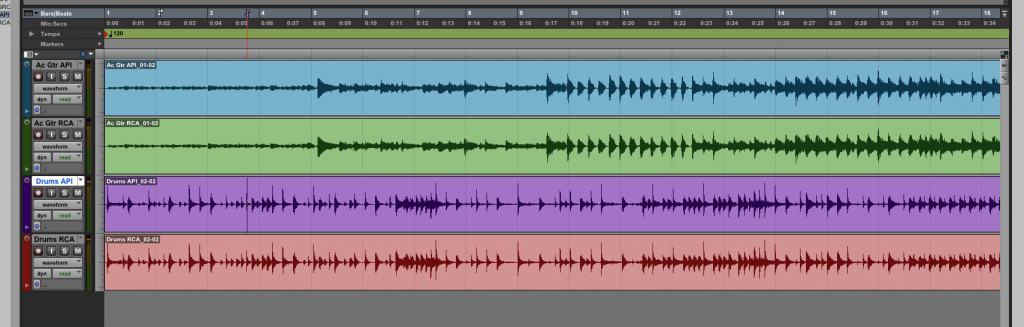

Anyhow. That’s it for now. As soon as I have a minute I will provide some audio test examples; I’ll post some A/B examples of this unit versus an API 512, hopefully with both acoustic gtr and drums.

Thanks to DW at EMRR for helpful suggestions regarding this project.

***UPDATE*** Listening test has been done and results are posted here.

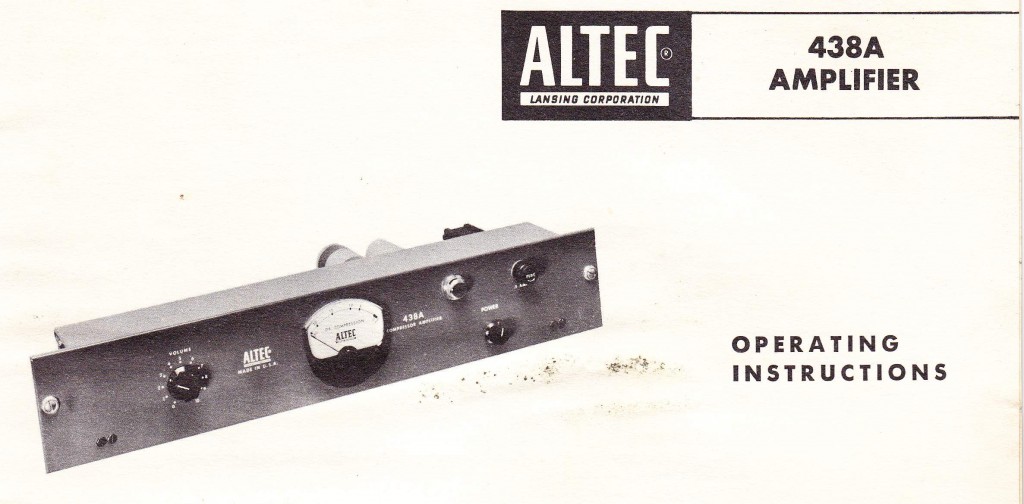

As we discussed in previous posts, the Altec 438A is an audio compressor designed in the late 1950s primarily for use in public-address sound systems. It has a microphone pre-amp built in, and an absolute minimum of controls: one knob determines the level of the signal that hits the input of the compressor; turn this knob all the way down and you hear silence; turn it high enough and you get a highly-amplified version of the input signal; keep turning it up and you get a highly amplified signal with the peaks attenuated or ‘compressed.’ There is also a 2nd input with slightly less gain; this unbalanced 100k ohm nominal input shares the same volume pot as the mic preamp. I suppose that the 438A was useful enough in its day, as there are hundreds still to be found; but for use in a modern music-production environment, it’s pretty useless. The levels are all wrong, there is not enough control of the compression parameters, and there is no proper balanced line-level input.

As we discussed in previous posts, the Altec 438A is an audio compressor designed in the late 1950s primarily for use in public-address sound systems. It has a microphone pre-amp built in, and an absolute minimum of controls: one knob determines the level of the signal that hits the input of the compressor; turn this knob all the way down and you hear silence; turn it high enough and you get a highly-amplified version of the input signal; keep turning it up and you get a highly amplified signal with the peaks attenuated or ‘compressed.’ There is also a 2nd input with slightly less gain; this unbalanced 100k ohm nominal input shares the same volume pot as the mic preamp. I suppose that the 438A was useful enough in its day, as there are hundreds still to be found; but for use in a modern music-production environment, it’s pretty useless. The levels are all wrong, there is not enough control of the compression parameters, and there is no proper balanced line-level input. Here is how I took an original-spec 438A and modify it so that one could use it alongside more modern compressors in a music-production studio.

Here is how I took an original-spec 438A and modify it so that one could use it alongside more modern compressors in a music-production studio. (From Left to Right): A switch to determine if either the two-stage mic preamp OR a balanced 15K nominal signal hits the input transformer of the compression amp; a threshold/ratio combo control ala the later Altec 436C; (top) an balanced output level control/pad ala the Gates Sta-Level (see here for details); (bottom) a release time control ala the Altec 436C. The original volume pot still functions as an interstage gain control for the mic preamp.

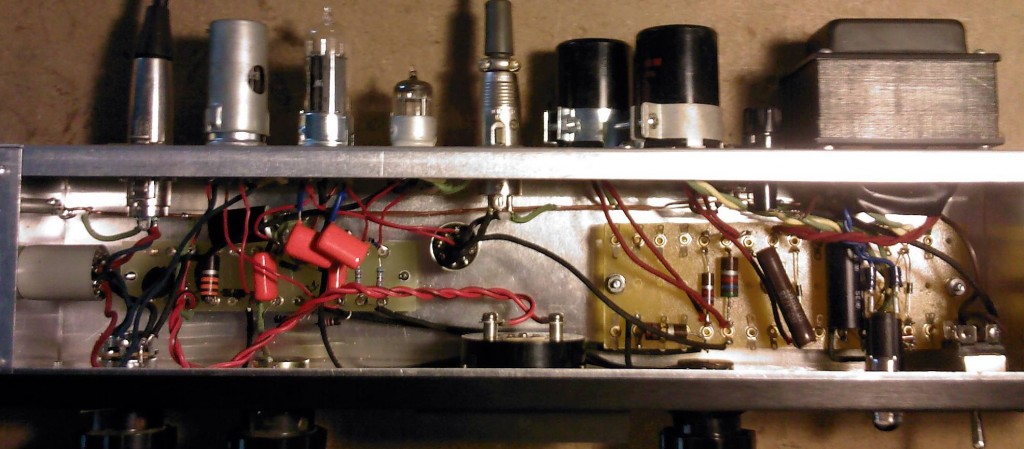

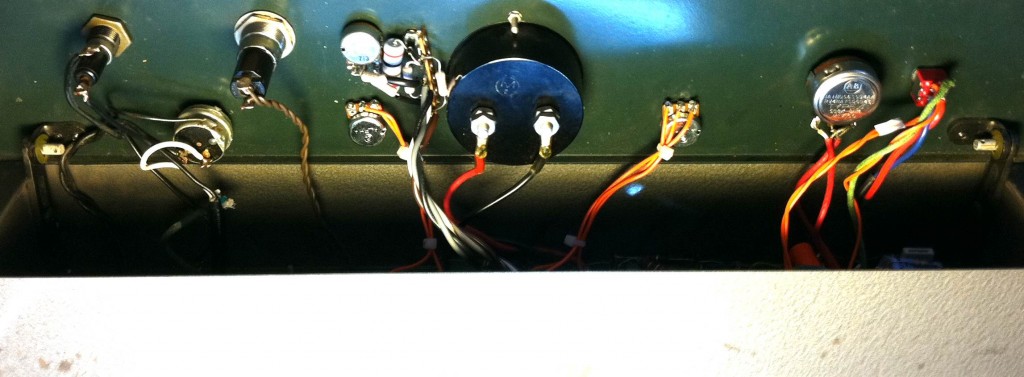

(From Left to Right): A switch to determine if either the two-stage mic preamp OR a balanced 15K nominal signal hits the input transformer of the compression amp; a threshold/ratio combo control ala the later Altec 436C; (top) an balanced output level control/pad ala the Gates Sta-Level (see here for details); (bottom) a release time control ala the Altec 436C. The original volume pot still functions as an interstage gain control for the mic preamp. Here’s the unit with the face flipped down, revealing the wiring to the newly added pots and switches. At my client’s request I used 11-position detented pots; ALPHA makes these in a huge range of values and Mouser stocks them for just about $2 a piece. A great value IMO. I used sliver-plated 24ga stranded wire for the audio wiring and 22ga solid copper for the control signal wiring.

Here’s the unit with the face flipped down, revealing the wiring to the newly added pots and switches. At my client’s request I used 11-position detented pots; ALPHA makes these in a huge range of values and Mouser stocks them for just about $2 a piece. A great value IMO. I used sliver-plated 24ga stranded wire for the audio wiring and 22ga solid copper for the control signal wiring. This 438A is now ready for use in any situation where a gentle, vintage compression sound is desired. The input and output levels are what you would expect from a standard pro-audio compressor; the release timing is widely variable (but never very fast – this would cause some artifacts due to the way these simple vari-mu compressors function); and the threshold/ratio control will yield a wide range of results as well. Since the unit was in good physical and electrical shape, no re-tubing or re-capping was necessary.

This 438A is now ready for use in any situation where a gentle, vintage compression sound is desired. The input and output levels are what you would expect from a standard pro-audio compressor; the release timing is widely variable (but never very fast – this would cause some artifacts due to the way these simple vari-mu compressors function); and the threshold/ratio control will yield a wide range of results as well. Since the unit was in good physical and electrical shape, no re-tubing or re-capping was necessary.